Sustainable packaging,

the right solutions

for every product

Single-use food packaging compatible with sustainable development, that’s the “right packaging”, one that does just what it’s designed to do, and nothing more.

But getting there takes many small steps.

Since 2017, Nutripack has been implementing an ambitious R&D and innovation policy to find solutions for its customers in the food processing and corporate catering sectors.

One step at at time, one effort at a time.

Product eco-design

100% mono-material, 100% recyclable

45 million euros invested in alternatives to polypropylene (PP)

Reducing the environmental

footprint

of packaging

For 30 years, we have been manufacturing single-use packaging for 2,600 customers in the corporate catering sector and food industries across Europe.

All of these customers have one thing in common: they prepare fresh foods (ready-made foods, butter, rillettes, etc.) that would spoil without packaging.

Our mission is to find the right sustainable and suitable solutions to package these products.

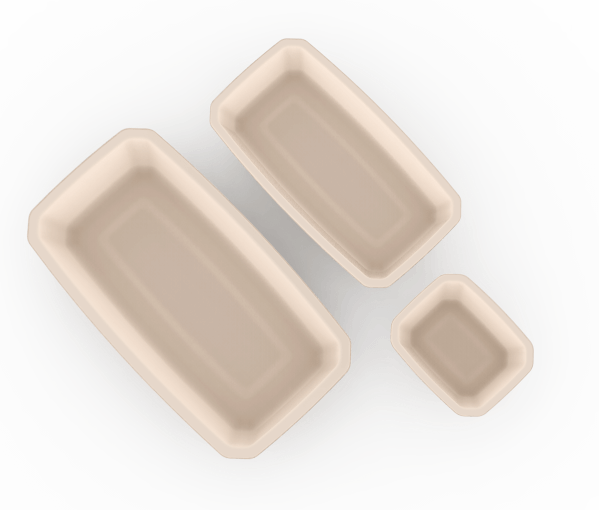

For all these customers, we create food containers, specific containers, tubs, boxes and lids whose materials, shapes and weight are always suitable and chosen carefully.

To provide what’s needed.

And only what’s needed.

A responsible approach

requires making choices:

We believe that there is no single solution.

Not everything is all black or all white, and you can’t transform an entire industry in a day.

But solutions do exist, and there are plenty of them.

Nutripack adapts each type of packaging to each need. And we have a variety of ways to reduce packaging’s impact on the environment:

- compostable, biodegradable lines

- recyclable lines made of mono-material plastic

- biosourced lines

Thanks to our innovative processes and a pragmatic approach,

we’re moving ahead together

Eco-design, an ethical approach for packaging with less impact

To design truly sustainable and responsible food packaging, making them biodegradable isn’t enough. We have to consider their impact throughout their entire life cycle. And we have to take the environment into consideration right from the start.

At Nutripack, eco-design looks at the entire packaging lifecycle:

- impact of materials

- impact of manufacturing in our factories

- end-of-life management

We only use high-quality raw materials

The choice of raw materials plays a fundamental role in facilitating recycling and guaranteeing food safety. It is also crucial to guarantee the quality of packaging and its sustainability.

All the raw materials we use are new and traced, and our suppliers are referenced and audited regularly.

And we go even further with our moulded cellulose food containers.

“Our 100% compostable food container production sites are located in Hauts-de-France and Occitania. The paper we use comes from nearby Saillat, a deliberate choice to reduce our manufacturing carbon footprint.

- The paper mills are PEFC and FSC (forest protection) certified.

- Water is recycled.

- Manufacturing waste is recycled.

- Moulded cellulose food containers are over 90% biosourced and their design is patented.”

We never forget that the products we make are used for food.

And of course, Nutripack is committed to the highest standards for each of our food containers: our Flines-lez-Râches and Mellac plants are BRC certified, your guarantee of compliance with food standards.

And we’re not done innovating yet!

Nutripack is Impact Group’s subsidiary dedicated to responsible single-use solutions. Since 2017, the group has invested more than 45 million euros in research and development. Innovation is our engine, and the road to minimal impact is still long. So let’s move forward together!

Where you can find us

Our sites in France

150 route de Lallaing

59148 Flines-lez Râches

France

ZI Kervidanou 2

Lieu-dit La Magdeleine

29300 Mellac

France

32 rue de l’Ancienne Gare

01430 Saint-Martin-Du-Fresne

France

Nutripack in Belgium

Nutripack in United Kingdom

Unit 5 Kingfisher Way

Hemdale Business Park

Nuneaton, Warwickshire CV11 6GY

United Kingdom

Nutripack en Italie

Via Buozzi 26

20097 San Donato Milanese

Italia

Our sites in Spain

Carretera Sant Miquel s/n

Banyeres Del Penedes

43711 Tarragona

España

Our sites in Nederland

Merwedestraat 54

5347 KW Oss

Nederland

Our sites in Deutschland

Guttenhofen 1

94116 Hutthurm

Deutschland

Our sites in Romania

Traian street 113 a

115100 Câmpulung Muscel

Romania

France

France  Belgium

Belgium  United Kingdom

United Kingdom  Italia

Italia  Spain

Spain  Nederland

Nederland  Deutschland

Deutschland  Romania

Romania